Automated Home Farming

Alex Turner

smspsy @ stock.adobe.com

Why Agriculture is Turning to Tech

Regardless of whether we give much thought to the act of purchasing and consuming food, the global food system is a central pillar in our daily lives. But how much consideration do we really give to where our food comes from and what it takes to get it to our tables?

Once upon a time, factors such as seasonality, weather and climate affected the availability of food. This is no longer such a concern. Fresh food is available in supermarket aisles year-round: we do not have to give a second thought to what is in season. The food production and processing methods and complex supply chains involved in making food so available and so cheap also mean that we are have a tendency to overlook provenance - how and where food is grown, reared and caught.

Today, one in six people globally rely on imported foods. The UK, US, China, Germany and Japan top the list of top food-importing countries; in the UK, 95% of fruit and half of all vegetables are imported. In the middle of winter, while root vegetables and brassicas are in season in the northern hemisphere, we can still buy soft fruits such as blueberries that are grown wildly out of season and transported great distances to be stacked on our shelves.

In 1994, the publication of “The Food Miles Report: The dangers of long-distance food transport,” drew awareness to the concept of 'food miles,' meaning the distances, sometimes thousands of miles, that food can be transported from the point of produce to the point of consumption. But food miles is not just about distance, and indeed growing food domestically can be more energy intensive than importing it. So while local is often touted as the best way to lower the carbon footprint, in truth the carbon emissions from food are often attributed more to production than to transport. In 2008, an analysis of US food emissions found 83% of carbon emissions in the food system result from food production, with just 11% attributed to transportation.

Food waste is also a significant issue in the global food system. In the UK for example, 100,000 tons of food is wasted each year, the equivalent of 250 million meals. At the same time, the number of people using food banks in the UK has increased from 25,899 in 2008/2009 to nearly two million in 2019/2020.

Further, events such as the COVID-19 pandemic highlight just how vulnerable the global food supply chain can be to sudden and unexpected changes. In the early days of the pandemic, nearly three quarters of Canada’s beef-processing capacity was shut down while two processing plants struggled to contain outbreaks of the virus.

Therefore the question that we consider is how can technology contribute to a healthier, more sustainable food supply chain. AgriTech offers vast and ever-evolving solutions, and this case study will focus on one potential solution to the issues of food security, food miles and food waste, considering what microculture, and specifically automated home farming, can bring to the table.

Microculture

Microculture is a broad term that embraces mobile and micro-gardens designed to produce vegetables, fruits, roots, and herbs in reduced spaces, indoors or outdoors. It can work in a range of scales, from a unit in the home to a climate-controlled agricultural unit the size of a shipping container, able to grow all sorts of food for small-scale cafeterias, restaurants, or bars. By deploying vertical farming technology applications such as Smart LED Lights and Plantscrapers, gardens and greenhouses can also be arranged vertically to further optimize space. The designs provide modularity, mobility, and easy replicability, and can be constructed using re-purposed or upcycled materials.

Microculture gardens are a useful resource for producing a broad range of plant species, including leafy and root vegetables, fruits, and herbs. By reducing the distances between producers and consumers, prices could decrease, as shipping would no longer be a significant cost. In time, such a farming solution could occupy viable spaces throughout urban communities with small-scale, self-sustaining food forests. As well as providing a source of locally grown, healthy food to communities with next-to-zero waste. These ecosystems would also function as carbon sinks and living air purifiers.

Low-income neighborhoods that often lack access to healthy food could benefit by having their communities surrounded by microculture gardens that provide fresh produce throughout the year. The US Department of Agriculture estimates between 25 million and 30 million Americans live in so-called "food deserts"—areas that have limited access to affordable, nutritious food. By letting communities manage their micro-gardens autonomously, they could not only offer self-sufficiency but also an income source as cultivated food could be sold. Project Food Forest, based in Sioux Falls, South Dakota, is one such example of an organization that wants to eliminate food deserts by helping people grow their own food through public agroforestry and edible landscape design projects.

Microculture gardens can also be used to feed isolated groups of people, like maritime crew members or even astronauts during missions. Self-contained farms allow small-scale producers to grow a variety of items on-site and offer some of the freshest and most nutrient dense options possible to improve dietary habits.

Automated Home Farming

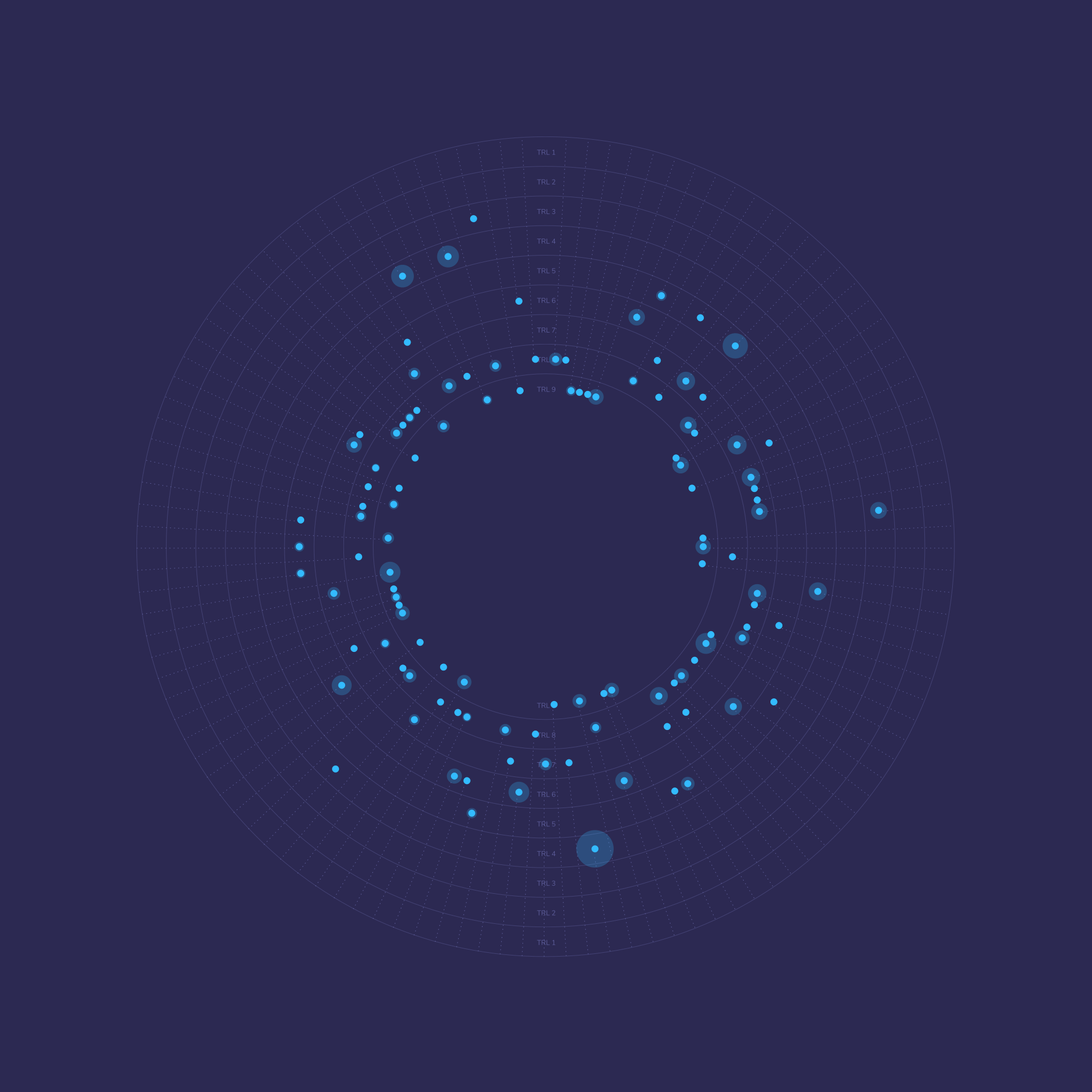

Strictly speaking, automated home farming covers computer-controlled "grow boxes" or kits that grow food autonomously in contained environments with minimal or no human assistance. The connected grow boxes are often hermetically sealed and lockable, WiFi-enabled and IoT connected, and also connected to electricity and a water supply. With the help of conventional probes and sensors such as humidity, moisture, and Nano Thermal Sensors, as well as Electrochemical Nanobiosensors, Smart LED Lights, and cameras, the grow boxes are connected to Mobile Crowdsensing Platforms, which monitors plant development and optimizes plant growth and yields by collectively learning from other plants and grow boxes on the platform and remotely adjusting the abiotic factors within each individual grow box.

Within the grow box, pH levels, light, temperature, humidity, plant heights, and water and nutrient levels can be monitored. Through indoor farming, grow boxes can perform a variety of farming functions, including seeding, watering, fertilizing, and removing weeds up to three times faster plant growth than conventional cultivation methods. To increase the level of accuracy, and depending on the plants cultivated, the user can access the Mobile Crowdsensing Platform and obtain further information about the status of their plants, access HD livestream video as well as growing plans and recommendations, or download the specific amount of water to irrigate the soil, the quantity of light dosed, or any other variable that addresses the needs of a particular species.

The type of cultivation enabled by automated home farming systems depends on the type of miniaturized farming controlled environment, which could be nutrient soil modules such as soil or coco coir substrates, or rockwool propagation cubes or grow slabs for hydroponics**.** From seeding, the user will likely only be responsible for monitoring the plant growth and harvesting when ready, as the necessary nutrients such as Nano Silica Fertilizers are all already generally incorporated in the soil or water in a hydroponics system. After one cycle of growth is complete, typically three months, seeds can be planted again and the consumables such as the nutrient soil module or substrate can be replaced.

Due to constant and optimal recirculation of water within the system, issues such as rot, mold, and bacteria can be avoided. In hydroponics systems, up to 95% of water is recycled. This is significant when considering that vertical farming saves up to 249 liters of water to grow a crop of lettuce compared to it being grown in a field. However, if the water within the hydroponics system is, or becomes, contaminated, it can be potentially harmful.

Inside a climate-controlled environment, crops are theoretically no longer vulnerable to stresses from natural elements. The sensors will detect whether plants are being excessively watered or if any fungi or bacteria have contaminated the production. Light levels can be monitored and adjusted depending on the stage of growth. Notifications via the app can alert the user so that specific substances can be applied or conditions altered to better nurture the plants. The app can also alert the user to which plants are ready to be harvested.

By automating and thereby simplifying the cultivation of crops on a lower scale to meet local demand, regions that lack access to fresh produce, for instance, could be empowered to achieve food sovereignty. Also, it holds the promise to improve the diet habits of the overall population by bridging the access to healthy produce, and thus better nutrition.

Currently, the cost of automated home farming systems averages around $2500, with power consumption reaching $20 a month. If automated farming becomes popular enough to reach houses and areas of the most need —not just individuals that can afford to pay for it— it may eventually be a great ally in fighting hunger worldwide. Also, together with crowd-sourced data provided by real-time crop monitoring platforms, interconnected gardens, and urban agriculture could maintain a cyclic interrelation between food production and its broader environmental, economic, and social influences.

Key Players

Seedo produces fully automated self-contained grow boxes to grow a range of vegetables, herbs, flowers, as well as some fruit via Plant Tissue Culture. The 55 kg devices are hermetically sealed in order to give the full control over temperature and humidity to optimize growth. An internal camera provides HD live streaming to allow for monitoring which can be managed on an app. Closed-loop watering systems reduce water consumption so that users only need WiFi, water, and a power source — the app takes care of the rest. Using full automation, one plant can be grown and managed at once. However, where a user is able to carry out manual intervention such as trimming, up to five plants can then be grown at once. Similar "plug and grow" devices have been developed by Rise Gardens, Aspara, and Agrilution's Plantcube.

Serving a larger scale, Growtune created the iFarm system to support vertical farms by collecting data and performing analytics for users to plan and optimize plant growth. Data comes from both open sources and its distributed network of users. Using machine vision, machine learning, and IoT-connected devices and sensors, iFarm uses an adaptive protocol to monitor plants and growing conditions to determine plant weight, growth deviations, and diseases, and can then adjust growth algorithms to achieve the planned yield. Growtune will even manage sales when it comes to selling produce.

US-based Growlink builds integrated software and hardware, nutrient sensors, controllers, and software platforms to provide real-time crop monitoring, data analytics, and alerts to increase productivity, yield, and even security for greenhouse and indoor vertical farming. Ready to use, drop-in units such as Fertigation can provide targeted nutrients with feed memory intelligence to improve crop yield while conserving conventional farm inputs such as labor, water, and fertilizer.

Gotham Greens pioneers hyper-local produce, operating five rooftop urban greenhouse facilities in New York and Chicago. According to Mr. Puri, CEO and co-founder, the glass and steel structures are controlled by computers that are "[...] able to monitor climate 365 days of the year, 24 hours a day, and make smart adjustments, data-driven adjustments, in order to maximise crop productivity, efficiency, reduce production losses." These systems use 95% less water and take up 97% less land than conventional farms.

Future Perspectives

Decentralizing agriculture by supporting local communities to grow their own produce offers a neat but powerful and sustainable alternative to mass agriculture. Intensive farming comes with its own set of challenges, with huge land take that permanently impacts natural ecosystems and replaces natural habitats with monocultures which strip the soil of much-needed nutrients while leaving us exposed to the risks of pests and disease.

By creating a network of small scale, local food sources, vertical farms, automated home farms, and microculture offer a far more sustainable way forward, bringing zero waste year-round food production closer to consumers. Long term, such practices may ultimately allow land that is currently used for agriculture to be restored and returned to more natural habitats.

And there are no real limits to what can be produced either, as vertical farming expert Paul Gauthier says, "(e)verything is possible. I don't think there is anything in the vertical farm that we can't grow."

Whether you choose your own microculture system to grow food, or source it from your local community farm forest or computer-controlled vertical farms, these alternatives to producing food offer practical means to access nutritious, affordable fresh produce in your neighborhood, or even directly from your own kitchen table. It isn't over for conventional farms, but AgriTech is finding ways to bring the outside inside, and indeed food production much closer to home.