Portable Factory

Laura Del Vecchio

© Itsanan @ stock.adobe.com

To support recent developments in manufacturing and supply chain logistics, as well as rapidly responding to customers' demands, a modular production business model could help factories keep up with the increasing demand for goods and services. By integrating technological solutions based on fields such as Additive Manufacturing, Robotics, Artificial Intelligence, and the Internet of Things (IoT), these portable factories could be placed anywhere.

The concept of these factories relies on converting cargo containers into mini-manufacturing places. The structure is capable of being packed, transported, and reinstalled at a new site in a matter of hours. The shipping containers need to have enough space to fit a variety of industrial components, alternatively, different containers could be destined for specific manufacturing purposes. The activity performed by these factories is controlled and monitored wherever they go by an integrated operation center.

Machinery-as-a-Service

As part of the post-ownership economy, this business model could evolve to machinery and robots on a subscription basis. With a shared calendar, each company or individual maker can reserve time with the machinery and program it to complete the desired task. Companies could also offer Micro-learning Platforms to help workers learn manufacturing process with ease. Some cloud robotics could be accessed entirely online, and the company can program the robot remotely. In other facilities, the company accesses it in person, sometimes with the guidance of a technician.

Machinery-as-a-Service brings several advantages to a regular factory model. First, by increasing the number of distributed shared machinery within a community instead of one centralized private facility, it enables the production to take place closer to the final consumer. By doing this, shipping, transportation costs, and emissions are reduced. Also, it allows small businesses to start production without the need for a substantial investment in machinery, democratizing production, and allowing creativity to flourish. Summing up forces with 3D printing machines and interconnected IoT devices, such factories allow for a very flexible production model.

3D Printing meets Portable

The progress in physical and digital workflows of Additive Manufacturing (or more commonly known, 3D Printing) is opening up unexpected possibilities and allows an integrated design of product and production system. This could pave the way to a scenario that mirrors the concept of Intention Economy, a system in which demand would link the supply chain closer to the consumer and where vendors respond according to customer needs instead of vying for the attention of many. Rather than being entirely passive, consumers are also gaining empowerment to become producers themselves, or prosumers within a global manufacturing community, where some can print their products remotely with the help of 3D Printing machines or renting a portable factory to fulfill their needs at a certain moment instead of buying an entire factory floor.

In terms of sustainability, reconfigured value chains and simpler supply chains could lead to more localized production, especially when combined with innovative distribution models. Furthermore, the ability to create parts on-demand could lead to improved resource efficiency and minimize inventory waste. Reducing inventory risk with no unsold finished goods could help acheive sustained revenue flow as goods are paid for before actually being manufactured.

Consumers can already access a website that teaches visitors how to build and customize given products. In times of fast-changing markets and short product life-cycles, manufacturing systems have to be adaptable and able to support a variety of products and product volumes. Production is becoming product-driven, and switching between different products should be possible with little manual intervention. Industries are going to need to undergo a rapid shift from mass-production to a hyper-customization of goods, providing the consumer with an extensive array of choices.

Future Perspectives

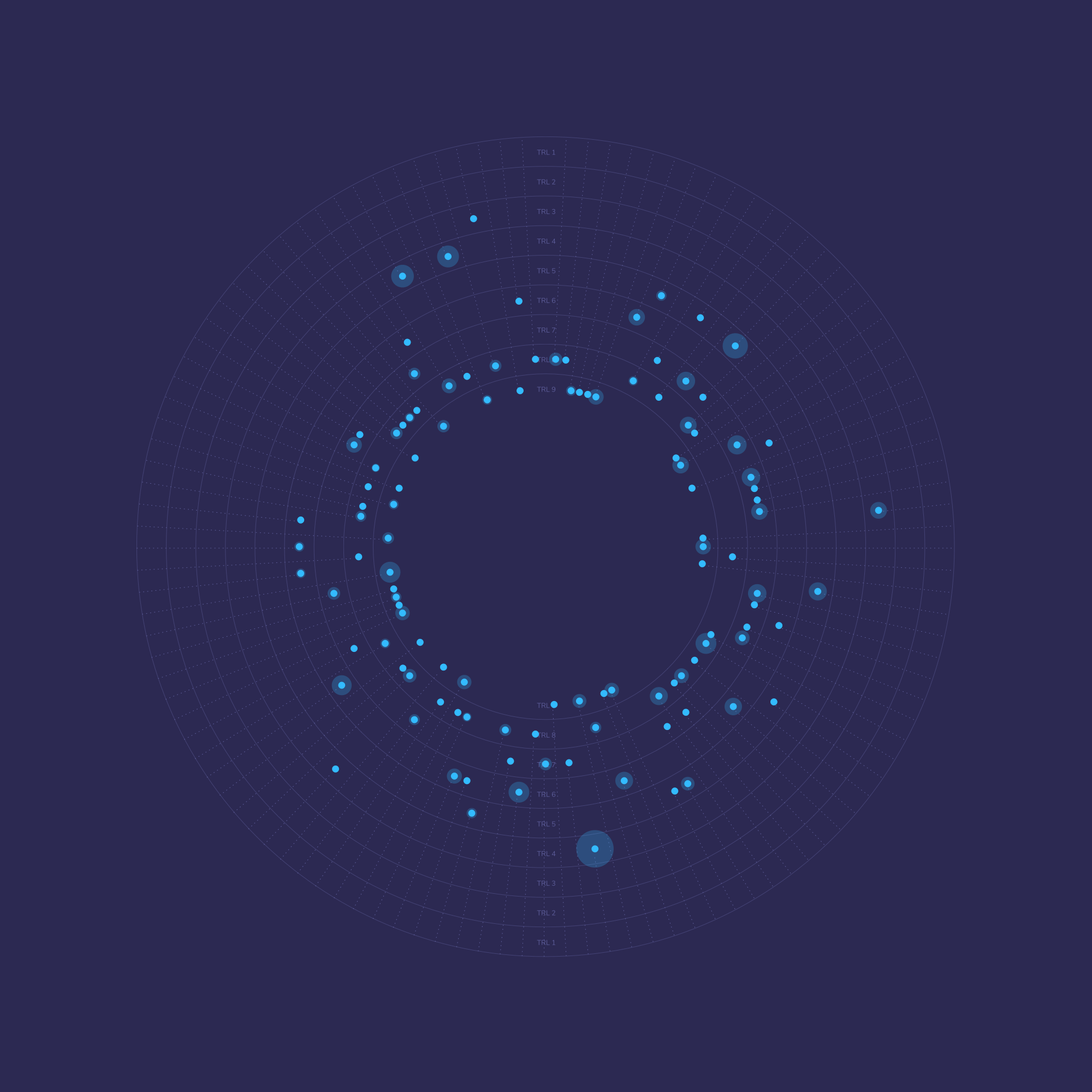

By using Machine Learning Data Analytics, future systems could collect a wide range of data, including customer tastes and material availability. It would allow systems to determine which type of product should be manufactured at any given time and pre-configure the multitude of design choices based on the customers’ unique taste. In combination with additive manufacturing, it would be possible to quickly adapt the product to market demands as the factories would be movable and easily adaptable. This scenario creates an exclusive range of possibilities while increasing profit and operational efficiency and reducing waste.

As products are manufactured on-the-go, it could improve quality assurance and time to market. The percentage of damaged items in logistics could also decrease. Depending on the demand and the distance of the shipment, manufacturing could as well be adjusted according to the route, being optimized to support specific flows. Also, the factory can be used for fast prototyping and new product making, thus supporting quick demonstrations before they are ready for mass production.

The complexity of taking the manufactured goods to logistics could be simplified as the process becomes one, thus enabling reduced energy consumption and costs. Besides that, to avoid damage in transportation, these factories could use assembly items in the country of destination by driving or shipping a container to the location, bringing companies closer to their international customers. Also, this business model could someday be applied not only in cargo production but also in domestic environments. This shift would disrupt the whole supply chain logistics, which could be limited to distributing only the assembly parts for the production at home, or the portable factories themselves.

On the other hand, as it is already known that individualism is deeply rooted in western societies, brands could easily manipulate customers by hiding behind slogans that defend the "power of uniqueness". Individualism long glued to consumerism in modern societies, has become an effective way for corporations to justify the maximization of profits while taking advantaged of people's desires and weaknesses.